Our Capabilities

Traditional cutting methods are slow and often too harsh for hard or delicate materials. Until recently, there were very few options that didn’t allow for a lot risk with materials—either from mechanical error or simply from a lack of tolerance for the materials themselves. Even standard materials like steel requiring exacting precision present challenges for traditional cutting methods.

ExpertWaterjet™ capabilities include cutting a wide range of materials for a variety of industries. Waterjet cutting is fast, versatile, and precise—capable of cutting materials from heavy steels to wafer-thin acrylics along with other materials like foam and granite. Expert Waterjet also offers a broad range of traditional fabrication services including drilling, sawing, punching, press braking and high performance paint finishes.

No Heat-Affected Zone (HAZ)

One of the unique advantages to waterjet cutting is the ability to cut material without interfering with its structure as there is no heat-affected zone (HAZ). ExperWaterjet™ uses water, as well as an abrasive component to precisely remove unwanted material. Unlike blades and lasers, there are no parts to create slag or burr the edges. Minimizing heat also minimizes the need for secondary processing—saving time and materials.

Tolerances and Edge Finish

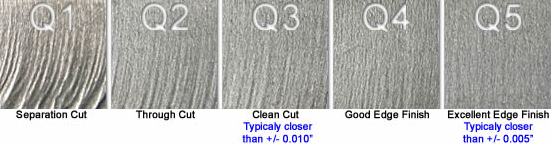

Waterjet technology has changed the way we approach cutting materials. While traditional cutting methods certainly still have their place in manufacturing, using a controlled abrasive allows for tolerances tighter than +/- 0.005". This is especially true for thinner materials. When tolerances are more flexible, speed increases and so does our ability to cut more in less time.

With thicker materials, tolerances may vary. Contact us more for more information.

Taper and edge finish are a direct result of cut speed. The faster the speed, the more course the edge. A smooth edge finish requires more time for a controlled cut.

5-Axis Cutting

Recent advances in technology have taken waterjet cutting to an even higher level of capability and precision. Instead of the normal X (back/forth), Y (left/right), and Z (up/down) axis, a 5-axis system gives us the capability of cutting on two additional axes—A (perpendicular) and C (rotation around the Z-axis). This flexibility allows for weld bevels and even 3-D parts.

- Welding

- Drilling

- Brake Forming

- Painting

- Surface Finishing

- Beveling

Materials

- Acrylic

- Aluminum

- Armor Plate

- Boron

- Brass

- Bronze

- Carbon Fiber

- Carbon Steel

- Cardboard

- Carpet

- Cast Iron

- Ceramic

- Cobalt

- Composites

- Copper

- Cork

- Exotic Alloys

- Fiberglass

- Foam

- Galvanized steel

- Glass

- Glass Reinforced Composites

- Glass Reinforced Polyurethane

- Granite

- Graphite

- Hard Rubber

- Hardened Steel

- Hardened Tool Steel

- Hardwood

- Hastalloy

- High Density Polyethylene

- Hot Rolled Steel

- Inconel

- Invar

- Kevlar

- Kovar

- Laminated material

- Laminates

- Limestone

- Magnesium

- Marble

- Mild steel

- Mirror Glass

- Monel

- Mylar Laminates

- Nickel Alloys

- Nylon

- Paper

- Plastic

- Plastic Films

- Plexiglass

- Polycarbonate

- Polyurethane

- Porcelain

- PVC

- Quartz

- Recyclyed Materials

- Rubber

- Soft Gaskets

- Soft Polyurethane

- Soft Rubber

- Spring Steel

- Stainless Steel

- Steel

- Steel Hardened

- Steel Mild

- Stone

- Tantalum

- Teflon

- Terrazzo

- Thermoplastics

- Thin Foils

- Thin Wax

- Tile

- Tin

- Titanium

- Tungsten

- UHMW

- Urethane

- Vinyl

- Wood

- Wrought Iron

- Zinc